All Training Presentations Free

Let's enhance your skill

Research has shown that additional training has a positive impact on a person’s employment opportunities. Acquiring new skills and competencies can extend options for professional advancement and offer additional career choices. There are also indications that VET may contribute to reducing unemployment and protect people from becoming unemployed in the first place.

A revolution in Manufacturing: The smed System Book by Shigeo Shingo

What is quicke changeover & SMED

Hi there, my name is R>S.Randy and I'd like to welcome you to the RMG TECH: Free Quick Changeover/SMED Course. We're going to introduce Quick Changeover, as well as, a powerful Lean concept known as SMED or Single Minute Exchange of Dies. And specifically by the end of this module, you'll know what both Quick Changeover and SMED are, as well as, why Quick Changeover is so important.

And we'll wrap this module up by introducing The 8 steps to Quick Changeover. And lastly, similar to our Dealing with the 7 Deadly Wastes course, we'll be visiting with the Lean thinkers of Ram Technologies throughout this course as we witness an actual Quick Changeover event take place. But first things first. Let's start off by defining exactly what we mean when we refer to a changeover. Well formally defined in manufacturing terms, a changeover is simply the amount of time taken to change a piece of equipment from producing the last good piece of a production lot to the first good piece of the next production lot. And if you work in a hospital or office area or any other non-manufacturing environment, simply replace the words last good piece with last good unit of one type of work.

Now one of the best ways to learn about quick changeover is to watch a pit crew operate at a Formula One or NASCAR race. It goes without saying that the ability to get the car back onto the track as quickly as possible can mean the difference between winning and losing. And so it is with producers of any product or service. We too need to be able to get our equipment or value added processes up and running as quickly as possible. Now to make sure we have a good grasp of this definition, let's look at a simple example. First, let's assume we're running product A.

And let's also assume we come to the end and we've successfully produced a product A and the machine stops running. Since the operator knows they must now get prepared to run product B, they begin the changeover process which might include gathering the needed parts, tools, drawings, paperwork, and work instructions. Well all of this results in machine downtime which is pure Muda, or waste, since no value is being created for the end customer. Finally after some time, the operator is able to get the machine ramped up and is busy fine tuning and tweaking things as they produce the first good part which we're calling product B here.

Now once the operator has successfully produced a product B, the changeover is complete. Okay. Well let's envision a worst case scenario. Let's imagine the operator has made it all the way to the end and has produced a product B only to learn it's defective in some way. Well the question is, is the changeover complete or not? The answer is no. It's not. Since again, the definition of a changeover is the amount of time taken to change a piece of equipment from producing the last good piece of a production lot to the first good piece of the next production lot.

Alright. So that's what changeover is. Now let's learn what this thing called SMED is all about. Well SMED, which stands for single Minute Exchange of Dies, is a system focused on dramatically reducing the time it takes to perform changeovers or setups as they're often called. SMED was actually developed 50 years ago by a man named Shigeo Shingo, who was working for the Toyota Motor Company as a consultant. Well in those days, Toyota needed to reduce inventory of automotive stampings and began looking for ways to perform changeovers in a more efficient manner. Well as it turns out, Shingo was able to collaborate with Toyota engineers on a method that reduced a four hour changeover on a thousand ton press to less than three minutes. Yes, you heard me right.

Four hours to three minutes! Now this example, as well as, an excellent description of the overall SMED process was documented in the book A Revolution in Manufacturing: The SMED System. So it goes without saying, if you don't already own this book I highly encourage you to pick a copy up. Now in later modules, we'll go into great detail as to how the SMED system can lead to lightning quick changeovers. But one thing I'd like to point out in this overview module is how much focus is placed on basic workplace organization and planning.

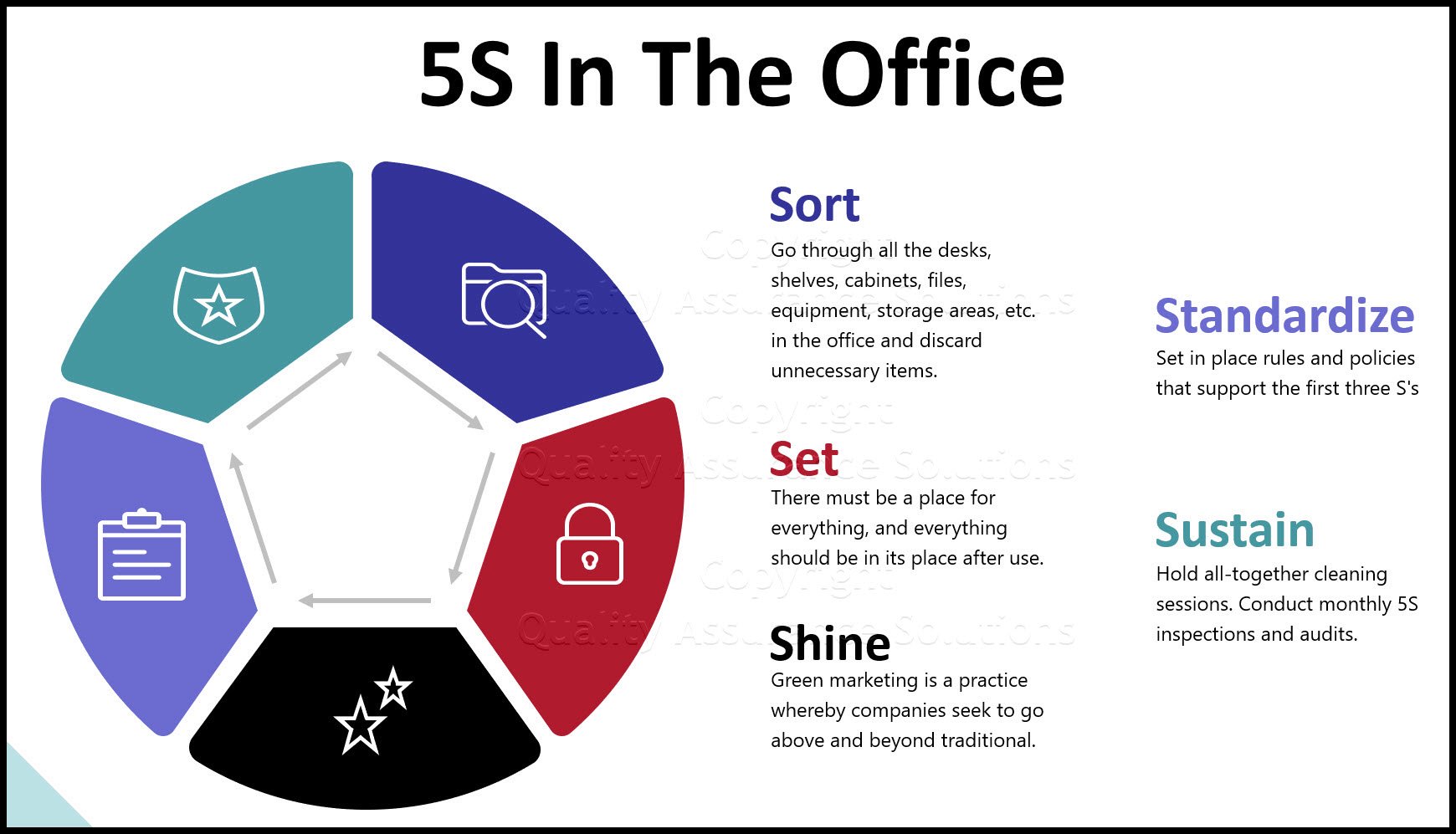

In fact, it's estimated that as much as 80% of the improvements identified by the SMED system are related to the techniques we've already learned about in the Gemba Academy 5S Workplace Productivity course. So to be sure, the primary focus of Quick Changeover and SMED is most definitely not on spending money for special tooling or expensive equipment. Alright. So that's what Quick Changeover and SMED is.

Now let's talk a bit about the benefits of Quick Changeover and why any of us should bother with it. Well the first reason for Quick Changeover is that is leads to the reduction of lead time. You see, Quick Changeover leads to increased velocity. In other words, you're able to create value faster when your machines are running and not sitting idle. You should definitely use this increase in velocity to your advantage. In fact, you can and should use it to increase customer satisfaction and grow your business.

Another reason Quick Changeover reduces lead time is related to lot sizes. You see, when lot sizes are reduced, the lead-time, or the time from when a customer orders a product until it's received, is also reduced. This is because much of the lead-time through a series of processes is nothing but waiting or queue time. In other words, the parts just sit and wait to be processed and moved on until the other parts in the lot are complete. Well let's look at an example. Here we see a manufacturing system with three pieces of equipment, Stations 1, 2, and 3.

Let's assume for this example, that this particular company is plagued with long changeovers and as such produces in large batches in order to better absorb the long changeover time. Specifically, this company produces in lots of ten. Meaning once the machine is setup and ready to go, they produce ten pieces and then move these ten pieces to the next process. And since the cycle time to process one part at each machine is one minute we know it takes at least ten minutes to get these ten parts from Station 1 to Station 2.

Then once the ten pieces arrive at Station 2, they're processed in one lot of ten and moved to Station 3. Once at Station 3, these ten parts are processed taking another ten minutes until the whole lot is complete. So as a result of batch and queue, the time to the first complete piece is 21 minutes and the time to complete the full batch is 30 minutes. Now let's look at what can happen when changeover time is reduced enabling the company to produce at a lot size of one, also referred to as Make one, Move one or One Piece Flow. We start with the ten pieces before Station 1.

But now instead of waiting for all ten parts to be done, we make one part at Station 1 and then move it to Station 2 with no waiting. Once Station 2 is done, we move the single piece to Station 3. A minute later, the first piece is complete and ready for delivery. So for those keeping score, the time to the first complete piece is three minutes. And the time to complete all ten pieces is 12 minutes.

In other words, the total lead time has been reduced by 18 minutes when compared to the Batch and Queue Method. Next, as a result of this improved flexibility and reduced lead time, Quick Changeover also improves on-time delivery performance. Let's look at a simple example to see why this is. Let's say a company is plagued with an extremely long changeover of 90 minutes.

And as such, once they finally get their machine setup and ready to go, they decide to run for 360 minutes in order to absorb as much of the changeover as possible. Now let's look at what happens when this 90 minute changeover is reduced to 30 minutes. When this occurs, the company is able to run smaller lots while also producing three different parts which could easily mean they're serving three different customers.

In other words, the customer that ordered some part C's, no longer has to wait several days for their parts like they would in the top example. Okay. Well so far we've talked about how Quick Changeover improves lead time and on time delivery. Now let's look at how it can lead to a dramatic reduction in inventory which reduces inventory carrying costs and increases cash flow.

0 Comments