RMG TECH Team

Jane Doe

Team Leader

Expert of Lean practices impelementation in industries.

www.rmgtech.in

Mike Ross

Trainer

Mike Ross is an expert of 5S and lean practices trainings

www.rmgtech.in

John Mark

Trainer

John Mark is an expert of 5S and lean practices trainings

www.rmgtech.in

Some FAQ

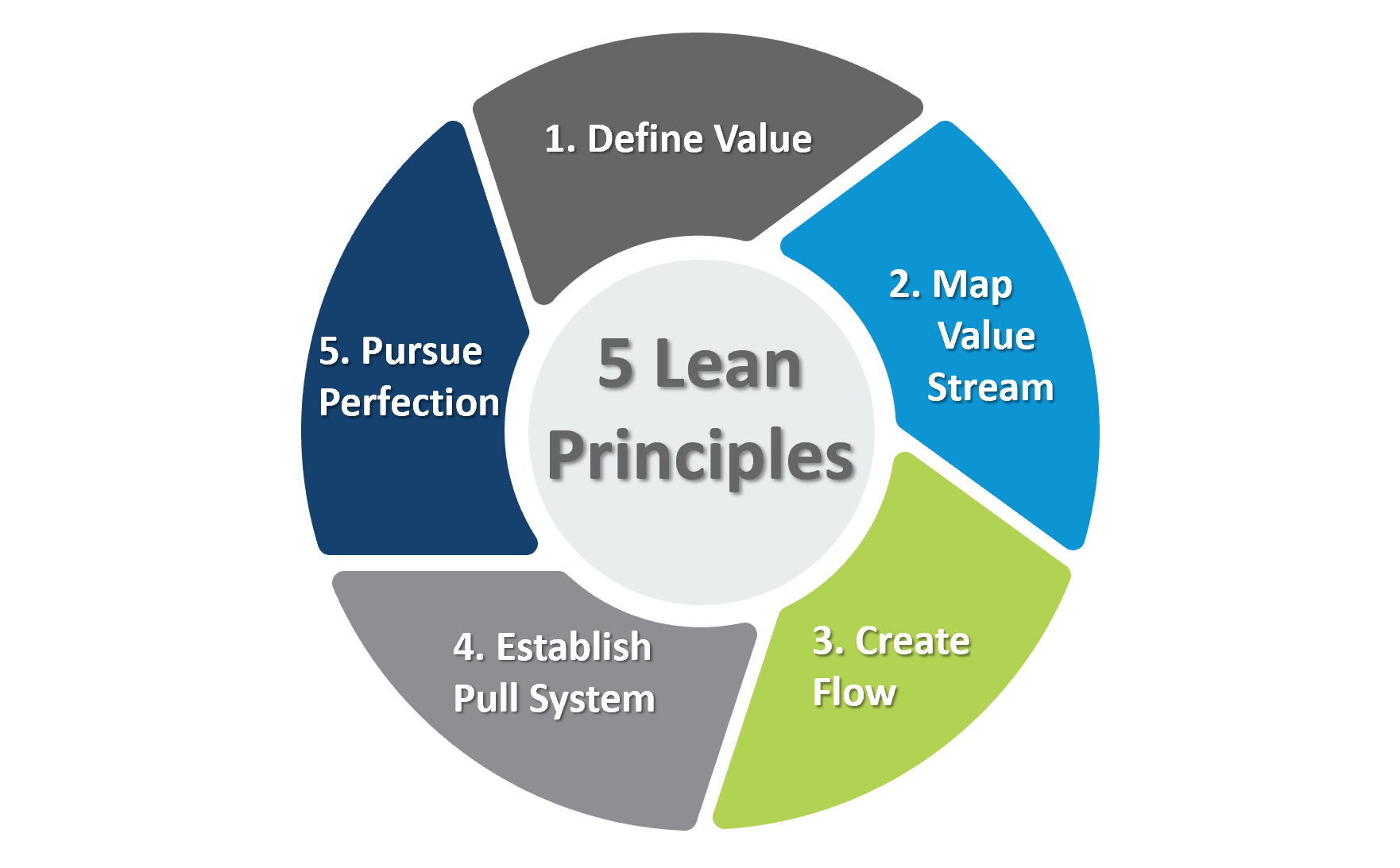

5S stands for the 5 steps of this methodology:

Lean manufacturing is a production process based on an ideology of maximising productivity while simultaneously minimising waste within a manufacturing operation. ... The benefits of lean manufacturing include reduced lead times and operating costs and improved product quality.

RMG TECH Services

All Tech Trainings

All Training Presentations Free

Let's enhance your skill

Research has shown that additional training has a positive impact on a person’s employment opportunities. Acquiring new skills and competencies can extend options for professional advancement and offer additional career choices. There are also indications that VET (Vocational education training) may contribute to reducing unemployment and protect people from becoming unemployed in the first place.

0 Comments